Global Know-how in heat expertise

Global Know-how in heat expertise

Conception

Fabrication

Installation

Entretien

Tradition and Innovation,, ![]() Fours et Réfractaires has become your heat Architect. Building on its past

Fours et Réfractaires has become your heat Architect. Building on its past ![]() it contributes to developing your future!

it contributes to developing your future!

From liquid metal to castings, SAS becomes a partner capable of working to stringent quality,

speed and precision demands to meet your requirements.

With ![]() Fours et Réfractaires, get to know all about Refractories, Heat Treatment and

Fours et Réfractaires, get to know all about Refractories, Heat Treatment and

Heating resistances again.

A tailored service for your Furnaces and refractories projects

We offer a personalised support service to ensure that we are always able to best meet your

requirements.

A family-run company, an industrial organisation

Created in 1934 by Henri Garreau, ![]() designs and manufactures refractory products for cast iron, iron and aluminium melting.

designs and manufactures refractory products for cast iron, iron and aluminium melting.

We can support you to produce and process your parts by offering innovative solutions.

We accompany you throughout all steps in your project, from tailored creation to maintenance.

remains

![]() remains to date a company whose entire capital is held by members of the founder’s family.

remains to date a company whose entire capital is held by members of the founder’s family.

Since 1934, an inventive and innovative company!

1934

1934  1960

1960  1966

1966  1974

1974  1980

1980  1990

1990  1995

1995  1996

1996  1997

1997  2000

2000  2003

2003  2012

2012  2013

2013 1934

Company creation by Henri Garreau.

The company designs and manufactures refractory products for cast iron and aluminium foundry.

1960

Cornering of the refractory products market by introducing new products and fitting techniques using gunning machines designed in-house.

1966

Broadening of the product range to dry products for electric furnaces.

1974

Oil crisis, the foundry world is damaged by the disappearance of 50% of all French foundries. The company undertakes a profound alteration of its production tool.

1980

The company opens onto new refractories businesses, with the expansion of its activity to heat treatment.

1990

Design and creation by the company of the first heat treatment furnace.

Development of a thermal engineering department.

1995

ISO 9002 certification issued by AFAQ for the manufacture and distribution of refractory products

1996

Initiation of an active partnership with SEVA (SAINT GOBAIN) for the development of special glass baking furnaces.

1997

Development of a siliceous product application prototype.

2000

Manufacture of 6 aluminium melting furnaces, one of which with a 45-tonne capacity.

2003

ISO 9001 V 2000 certification.

2012

OTTO JUNKER representation for induction aluminium melting and heat treatment furnaces.

2013

Agreement with I2R for the distribution of silicon carbide and MoSi2 resistances.

Expert in refractory products: morethan 20,000 tonnes produced eachyear

Refractory products remain the core of SAS’ business, whose 85 years of experience in this field makes the company a specialist.

We specialise in defining our customers’ needs to optimise the best refractory product in the right place.

Specialist in the manufacture of refractory products, promoting the quality of its raw materials.

Specialist in the application of its own refractory products.

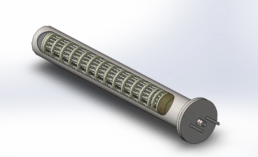

Our industrial furnaces: from the automotiv industry to the space sector

In response to its customers’ specific needs, ![]() can manufacture furnaces or

can manufacture furnaces or

complete processing lines, fitting perfectly into an existing manufacturing process

thanks to an excellent understanding of its customers’ industrial environment.

Having already successfully met the requests of customers in the automotive,aerospace, mining and cosmetic industries,![]() offers you its know-how!

offers you its know-how!

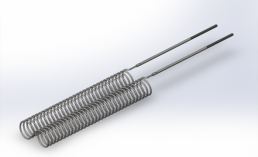

Heating resistances: design, creation and maintenance.

Whether metal or ceramic, the resistances![]() are designed to last.

are designed to last.

Made from Fe Cr Al or Ni Cr, in wire or strip form, whether coiled or hairpin, les résistances

métalliques ![]() metal resistance are made to measure to complete efficiency.

metal resistance are made to measure to complete efficiency.

Whether SiC or MOSi 2![]() works with I 2 R, the market reference.

works with I 2 R, the market reference.

Our furnaces and refractories company in a few figures

Of the French foundry market are![]() customers.

customers.

Export revenue

Service action revenue

Nos 12 plus gros clients nous confient leurs équipements depuis plus de 20 ans

Une équipe d'ingénieurs dédiée à la Recherche et au Développement

400 clients dont les plus grands noms de l’industrie européenne, PSA, Thyssen, Renault, Mittal ....

400clients

including the biggest industries

5000m2

of floor space in Nanterre

3

DO engineers

20 000T/AN

refractory products

27personnes

Work for us

85ans

of experience

Our quality process

- Strong personal involvement and training

- Close technical partnership with our customers

- ISO 9001 certification

- Traceability