Metal electric heating resistances are made from a resistive nickel-chromium (NiCr) or iron-chromium-aluminium (FeCrAl) strip or wire.

The maximum operating temperatures are:

- 1250 °C for the NiCr alloy

- 1350 °C for the FeCrAl alloy

Our main creations are:

- Coiled wire resistances

- Hairpin wire or strip resistances

- Heating glow plugs

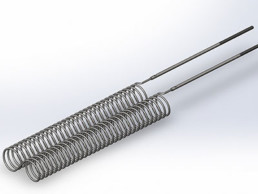

Examples of coiled wire resistances that we manufacture

Coiled wire resistance

The resistance consists of one or more coils or “rays” connected by bridges.

At each end, the outputs may be:

- Single wire

- Twisted double or triple wire

- Rod, with or without end thread

The areas of application are diverse:

- Thermal treatment furnaces

- Ovens

- Aluminium smelting/holding furnaces

- Indirect bath heating

- Glass furnaces

- Ceramic and porcelain furnaces

- Incinerator furnaces. . .

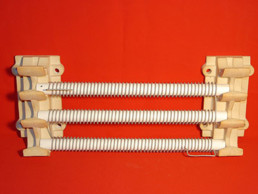

Hairpin resistances can be used with various types of support:

- Fitted onto smooth or threaded ceramic tubes

- Bracket-mounted

- Inserted into ceramic parts with grooves

- Partially embedded into concrete or fibrous material

We can make the ceramic holders suited to your needs, along with more elaborate assemblies.

Contact us and/or request the technical data sheets for our metal heating resistances.

Hairpin wire or strip resistances

The resistance consists of a series of waves. It is fitted at each end with outputs for cold connections

The areas of application for hairpin resistances are also varied:

- Thermal treatment furnaces

- Glass furnaces

- Continuous annealing lines

- Indirect bath heating

- Galvanising furnaces. . .

Contact us and/or request the technical data sheets for our hairpin heating resistances.

Some examples of hairpin resistances that we offer